Security Inks and Coatings for Product Verification and Traceability

Microtrace security inks range from visible novelty effects to covert, high-security systems. Each solution is tailored to your risk profile, print process, detection method, and budget, delivering consistent product protection from production through market distribution.

Security Ink That Fits Your Needs

Not all “security inks” deliver meaningful protection. Many rely on additives that are easy to duplicate or mimic. Microtrace develops security inks engineered for lasting security, tailored to your risk profile and strategic goals.

- Visible inks for basic product distinction or consumer engagement

- Covert inks for detector-based verification

- High-security systems incorporating Spectral Taggant™ and the Summit™ Authentication Platform

Microtrace taggant chemistries can be formulated into water, solvent, UV, or LED curable inks, and are compatible with common print methods including flexographic, offset, lithographic, rotary-screen and ink jet.

Two Security Ink Solutions from One Trusted Source

Standalone Security Inks

Custom-formulated with Microtrace taggants for visual or machine-readable authentication.

- Options includeMicrotaggant® particles, Enhanced Phosphors, IR-Visible Phosphors, and IR-to-IR Phosphors

- Delivered as bulk taggants, ready-to-use ink, printed security labels, or taggant transfers

Integrated Authentication Systems

The Summit™ Authentication Platform delivers a complete solution with optimized detection and analytics.

- Utilizes Spectral™ Taggant signatures and Encrypted Barcodes

- Validated through mobile app, handheld detectors or integrated smart devices

- Includes Alerion™ AI classification with optional secure cloud reporting

- Fully aligned across formulation, application, and detection tools

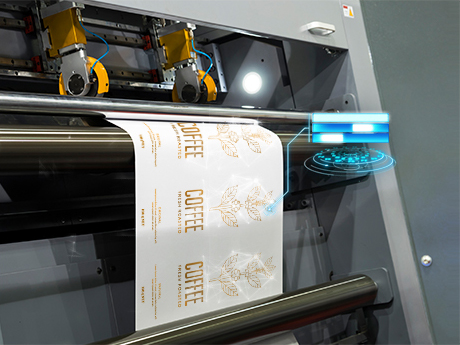

Printing Considerations

The security of taggant signatures depends on consistent print execution. Microtrace ensures proper print processes and production tolerances by supporting:

- Collaboration with printers to align on equipment, print procedures and tolerances

- Recommendations for print quality control and equipment requirements

- In-line taggant readers to detect errors in real time

- Delivery of pre-printed labels or taggant transfers when needed, reducing risks from multiple print locations

Custom Guidance. Proven Results.

Security ink must perform under your specific conditions. Whether you're protecting FMCG products, identification documents, or items exposed to prolonged of outdoor exposure, Microtrace designs ink systems to meet your real-world challenges.

- Appropriate ink and taggant technologies

- Printing constraints and process variables

- Detection methods and reader specifications

- Risk points across your supply chain

Your Partner for Custom Security Inks

From formulation through final verification, Microtrace delivers complete, field-proven security ink solutions tailored to your products, processes, and real-world threats.