Custom Laser Systems for Covert Brand Protection and Traceability

Microtrace designs laser systems around your application, not the other way around. Each unit is configured to meet specific marking objectives, material requirements, and production environments. These systems enable covert security features that strengthen brand protection, support regulatory compliance, and ensure product traceability. Whether integrated into a production line or deployed as a standalone station, Microtrace systems deliver precise, consistent marks on even the most challenging surfaces.

Tailored Laser Systems

Microtrace doesn’t begin with a stock unit. We begin with your requirements.

Each laser system is engineered to align with your material, marking, and production goals. Systems are designed for:

- Inline integration or standalone workstations

- High-resolution micromarking

- Consistent performance across diverse substrates

- Compatibility with production scale and workflows

All systems are built for precision and reliability while maintaining material integrity.

Applications

Common use cases include:

- Invisible barcodes on eyeglass frames

- Logos and microtext on precious stones

- Traceability marks on fine wires and aerospace components

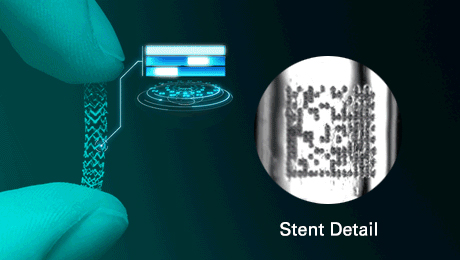

- UDI and barcodes on medical devices

- Pharmaceutical tablet micromarking

Whether for compliance, branding, or traceability, Microtrace laser systems deliver high-fidelity marks that perform reliably in real-world conditions.

Contract Marking Services

Not ready to invest in equipment? Microtrace provides contract part marking with rapid turnaround. Using our in-house systems, we deliver precision marking on nearly any surface down to the sub-micron level without capital expense.

Laser system capabilities include:

- Excimer: High-precision applications.

- CO₂: Versatile material marking.

- Pico and Femtosecond: Ultra-fine marks.

- Nd:YAG: Deep marking on metals and hard materials

- Fiber Optic: Efficient, scalable marking

Our engineers optimize parameters for clarity, durability, and consistency.

Laser R&D and Pilot Support

Unsure which laser or setup is best for your application? Microtrace offers full R&D and pilot support, including:

- Material, additive, and mark strategy evaluation

- Lab-based proof-of-concept testing

- Scale-up planning and transition to production

We help you validate the right configuration before committing to full-scale deployment.